What constitutes an arc test failure?

Per IEEE standard, a failure is indicated by violation of any conditions listed below.

- There should be no permanent deformation of the structure, and secured covers and doors do not open. (Slight bowing or other distortion is permitted as long as such deformation does not extend to the indicator mounting.)

- No indicators burn. However, pin holes and discoloration of indicators is permitted.

- Ejection of small parts (up to 60 g) through the plenum is permitted.

- No parts are allowed to eject through seams or doors of the structure. A high speed video is used to further analyze the results of an arc test if needed. All grounding connections remain effective after the test.

Failed Arc Test

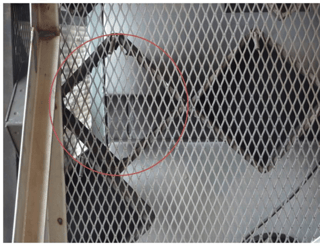

Failed Arc Test

The image above shows failure of an arc test. One indicator is burned completely causing the failure.

A Successful Arc Test

The image below shows a successful arc test done at KEMA Power Test lab in Chalfont, PA.

- The arc and gases exhaust through the plenum as designed. Also, the structure did not bow appreciably and no cotton indicator was damaged in any way.

- It was done on a day when there was snow falling and one can see particles of snow with the exhaust gases in the picture.

- The IR windows used on Vesta did not rupture during the arc tests.

- Consequently, IR scanning of Vesta can be done with the equipment energized wearing no protective gear. Per IEEE standard, a failure is indicated by violation of any conditions listed below.

To Learn More

Download our free whitepaper titled "New Arc Resistant, Compact Metal Clad Switchgear: Meeting ANSI / UL Design Challenges" to learn how to meet the ANSI/IEEE/UL design challenges while still coming up with a compact, front accessible switchgear.