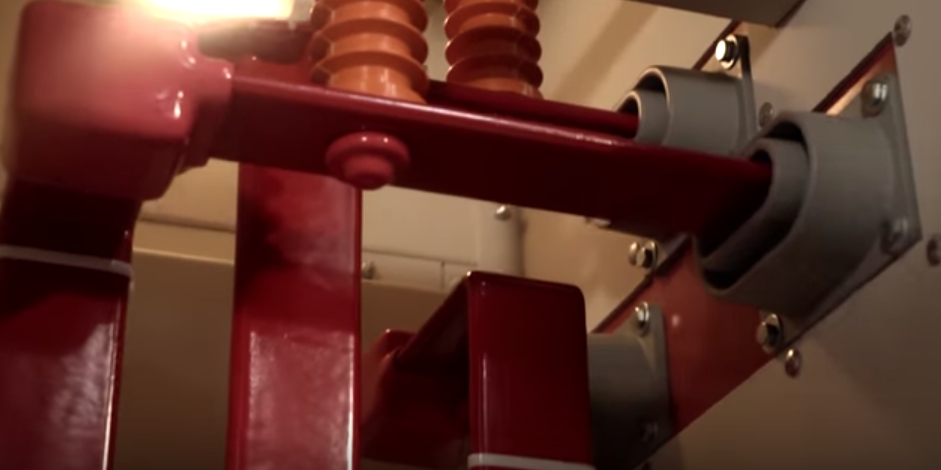

Bus bars used in switchboards are a critical factor in custom switchgear projects.

To cut their costs, many manufacturers may reduce the dimensional volume of their bus bars by as much as 25% to save material costs, by sizing their bus for 3,200-amp load, for example, when a 4,000-amp bus has been specified by the customer.

- While this smaller bus bar can pass the UL heat-rise test at 4,000 amps, it generates substantially higher heat during real-world operation at this load.

This excessive heat creates an oven-like atmosphere that can cause premature failure in other electrical components within the enclosure.

The IEM Difference

- Unlike other manufacturers who reduce the volume of the bus bars in their units to save costs, IEM switchboards feature a current density-rated bus with bus bars built to the full dimensional size and density required to support your maximum specified amperage load.

- The IEM current density-rated bus bar produces significantly less heat, which ensures long-term service life and reliability of the components within the switchboard enclosure.

- This advantage is especially important when specifying switchgear systems installed in smaller electrical distribution rooms. Because these heat effects are increased when electrical equipment is confined to these smaller spaces, temperatures can often exceed the UL 30° C (86° F) heat-rise ambient temperature limit.

Want to learn more?

To find out out how IEM’s unique design and manufacturing capabilities provide for the integration of various components or products into a single assembly with more bus and lower operating temperatures, simply click on the button below.